Term of Reference

DEVELOPMENT OBJECTIVE:

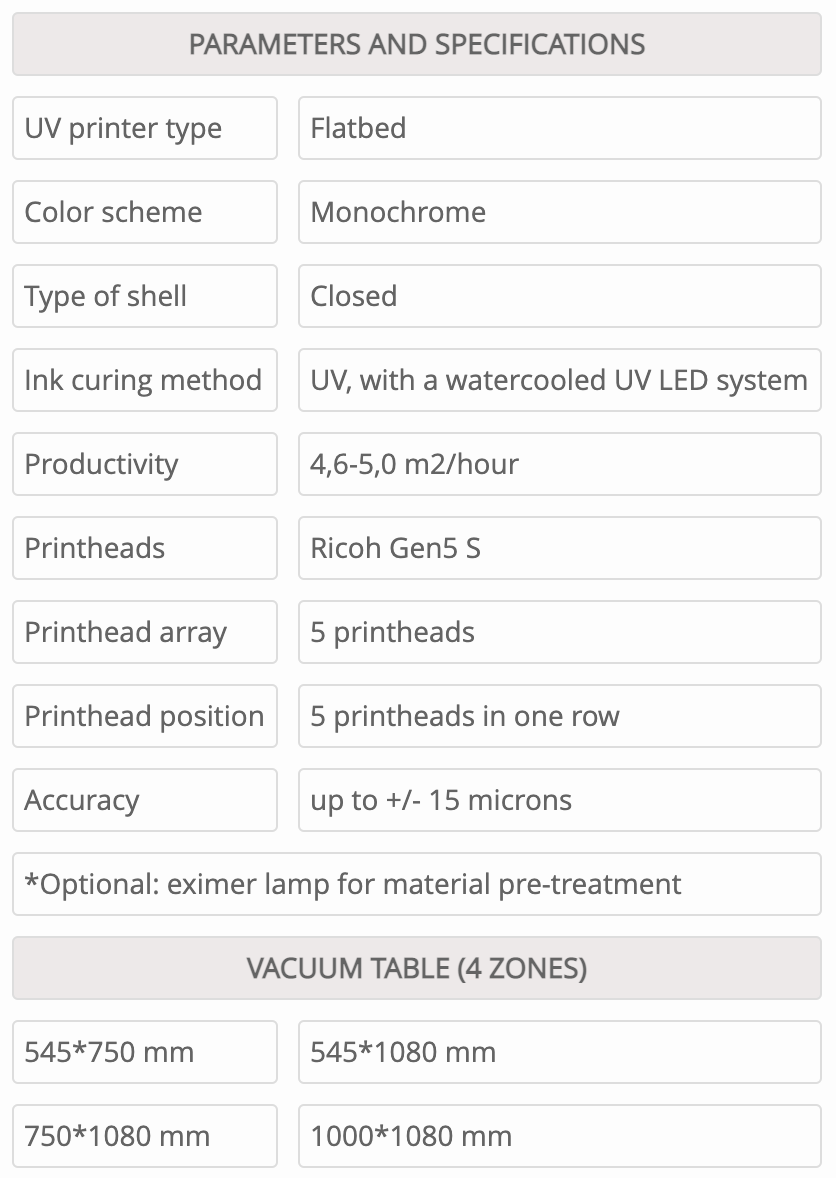

Creating a monochrome printer that provides high-precision digital UV printing on metal plates of any format.Providing visiual printing resolution up to 850 dpi, adressable printing resolution up to 5400*5400 dpi, with an accuracy of up to +/-15 microns, but no worse quality than +/- 25 microns.

MAIN PARAMETERS AND TECHNICAL REQUIREMENTS:

1 Color scheme: monochrome.

2 Water-cooled UV LED curing system.

3 Productivity 4,6-5,0 m2/hour.

4 Printhead Configuration.

• Ricoh MH5220 (GEN5S) printheads in the new configuration.

• Printhead position - 5 printheads in a row.

• Native printhead resolution 600 nozzles per inch.

5 Option of installing of an excimer lamp for surface pre-treatment to provide a higher adhesion.

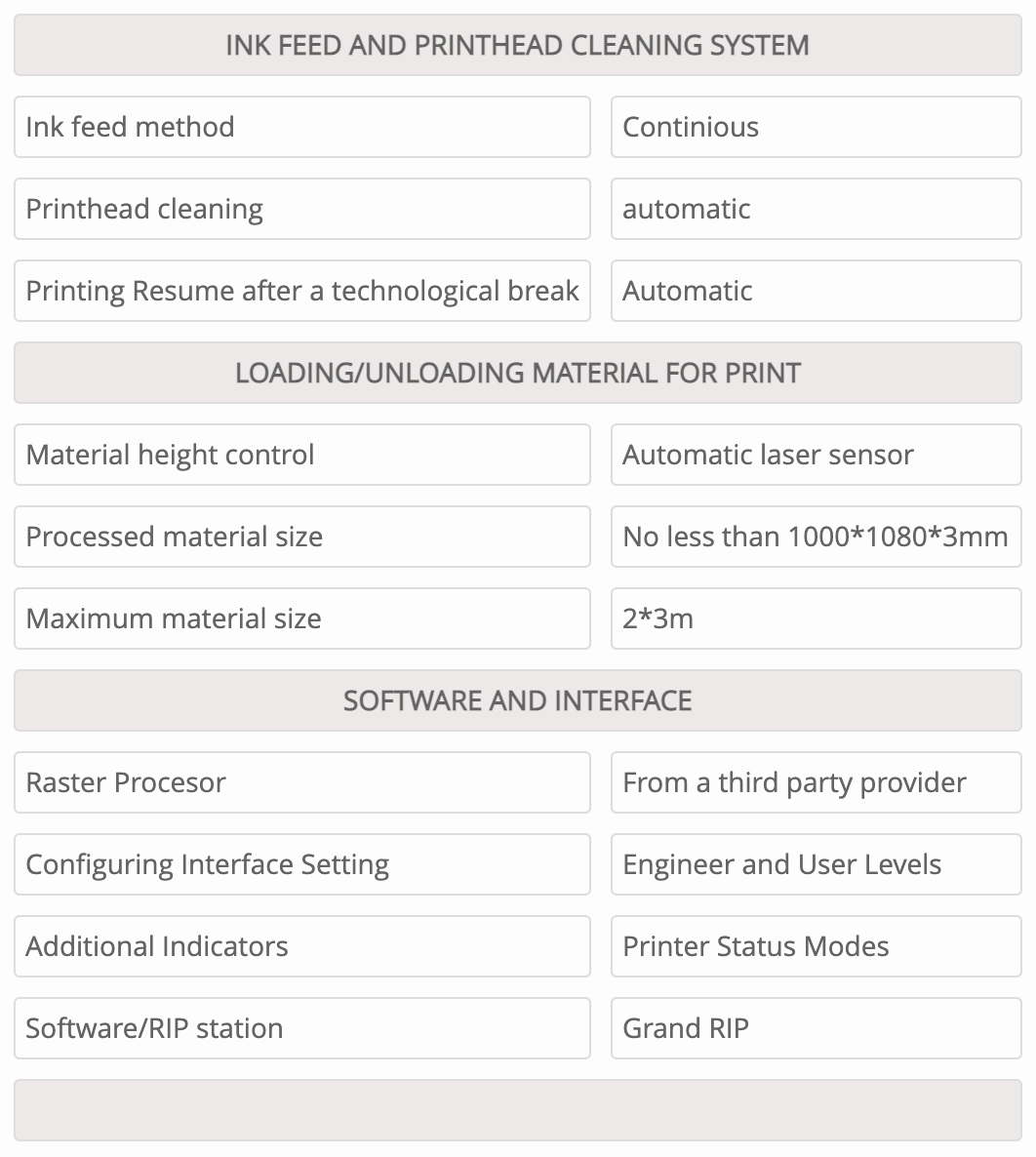

6 Ink supply and printhead cleaning system.

• Machine has ink continious supply system with the main tanks 5L each to subtanks located near printheads for stability.

• Automatic ink Level Control.

• Individual ink channel for each printhead with selective printhead cleaning possibility.

• It is also provides automatic printhead re-fill.

7 Loading/unloading of the print media.

• Safety control prevents printing with open loading window.

• Automatic height Control. The laser sensor keeps a constant distance between the material and printheads.

8 Vacuum table.

• Tolerance Flatness is +/- 0.05 mm.

• The printer area dimensions are up to 2*3 m.

• There is a system of pins and holes for easy positioning of the material.

• Four vacuum zones:545*750 mm; 545*1080 mm; 750*1080 mm; 1000*1080 mm.

• Adjustable vacuum strength.

9 Axis.

• X and Y axis are driven by linear magnetic system which gives stability and accuracy +/- 0.005 mm.

10 The software and printer interface includes:

• RIP.

• User/Engineer Acces Levels.

• Visual printer status indicator.