IQDEMY Fashion Technologies

The modern world of digital printing surprises every year more and more. Until quite recently, digital printing has just begun to expand the possibilities of its application, going beyond printing only on paper. Today we can see that it can be used on different surfaces, where it was impossible to print on before.

Advanced printing equipment is already used around the world in a variety of industries. Digital printing is actively used for printing on any surface (from hard plastics and metals to rolled fabric materials). Bright and saturated prints is not all that IQDEMY can produce. Here we have combined all our developed technologies to create new opportunities for the fashion industry.

You can get more detailed information about each of our technologies below:

TECHNOLOGY: PHOSPHORESCENT

shoes • watch industry • bags • suitcases • umbrellas • hats • eyeglass frames • buckle • handle • combination locks • fastener • fabrics

UV-curable fired glow dyes have an ability to store the light in the daytime and to issue it at night (one of the possible colours of the synthesis). Using inkjet printing, you can apply ink with phosphorescent on various hard surfaces as well as on flexible fabrics. The unique decorative glow effect guarantees a product fake protection as well.

TECHNOLOGY: WAVE-GUIDE

shoes • watch industry • bags • suitcases • umbrellas • hats • eyeglass frames • buckle • handle • combination locks • fastener • fabrics

Special titanium dioxide ink for printing plain wave-guide. In a day light there is a transparent pattern with closed or solid lines. With a laser it is possible to see a glowing pattern.

TECHNOLOGY: METAL ON METAL

watch industry • bags • suitcases • shoes • outerwear • buckle • fastener • ceramics • glass

There is an application of thick layers of soft metals to hard metals, ceramics and glass. An element applied by soft metal, as compared to engraving or etching, has a high abrasion resistance, because the technology involves the introduction of one metal into another (maximum protection from physical impact).

TECHNOLOGY: TEXTILE PRINTING

satin • velvet • velour • viscose • corduroy • suede • cashmere • leather • leatherette • lycra • linen • organza • crepe satin • twill • polyester • wool • silk • chiffon • cotton

Decorative printing on fabrics is aimed to relieve designers from restrictions and makes it possible to realize any print faster and cheaper, and at the same time a print run of it is not limited. There are no restrictions in terms of colour and composition. A full-colour image can be applied to any background due to the presence of white colour. The image is resistant to fading under the influence of sunlight and it withstands flexion and stretching, and finished product with decorative printing withstands repeated washing.

TECHNOLOGY: PRINTING ON COMPLEX TYPES OF FABRICS

capron • silicone • kevlar • elastomers

Every year direct printing becomes possible on more and more materials that have not been used for UV printing. Thanks to constantly updated ink formulations IQDEMY offers new solutions for printing on complex types of fabrics.

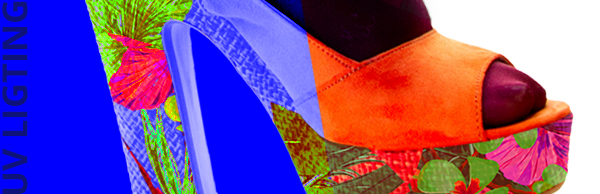

TECHNOLOGY: NEON INK

shoes • fabrics • watch industry • bags • suitcases • cases • umbrellas • eyeglass frames • sports equipment

IQDEMY Chemicals Laboratory created the technology of mixing fluorescent colourants and basic CMYK system pigments that gives really high-quality and bright colour patterns, “neon” colours both in a day light and in UV-light. Lean on this technology IQDEMY do not limit with two or three colours and can mix different patterns.

TECHNOLOGY: TEFLON COATING

shoes • fabrics • sports equipment • bags • suitcases • umbrellas • hats • outerwear • bathing suits

The technology is based on the use of such properties of Teflon nanoparticles as the water repellency (even oily moisture, dirt, etc.) and increased wear and fire resistance. Teflon is applied by digital printing on various types of surfaces due to its nano-dimension, covering a required area of a material. Printing teflon coating on clothes and accessories protect a fabric from adverse weather conditions, while preserving an excellent appearance of a product.

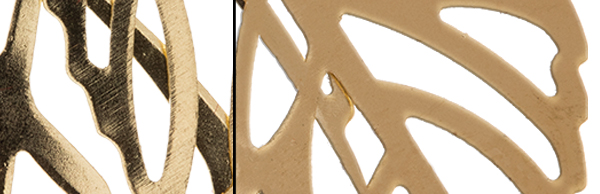

TECHNOLOGY: PROTECTIVE COATINGS FOR METALS

accessories (buttons, cufflinks, locks, zippers, clips, etc.) • watch industry • jewelry • lighters • cigarette cases

Protective metal coatings technology uses a protective varnish based on high-strength polymers with nanoceramic particles to protect jewelry or other metal accessories. This coating preserves the structure of a material, protects against abrasive effects, retains a glossy texture that eliminates the need to polish. According to customer's requests coatings can have different colours.

TECHNOLOGY: DEEP BLACK COLOUR

ceramic accessories and jewelry • watch industry • fabrics

Carbon nanotubes can to absorb almost all the light, this property is used when printing or spraying nanotubes on various surfaces and materials. The technology is used to create an aesthetic effect both on different types of fabrics and on expensive luxury items, including ceramic products (inks withstand the firing temperature of ceramics).

TECHNOLOGY: FABRIC MEMBRANES

fabrics • breathable waterproof clothing • casual wear • underwear • sportswear

Imagine that your casuals are breathable (it does not allow you to feel discomfort being in a stuffy room) and moisture-proof. Or let's assume that your clothes can take moisture that forms on the body to the outside, but not let it in, thereby providing a microclimate under your clothes under different external conditions. All this becomes possible due to the technology of applying membranes (small grids with selective transmittance).

TECHNOLOGY: SMART CLOTHES

fabrics • backpacks • outerwear • shoes • hats

The technology of applying conductive layers and elements of conductive inks on fabrics based on silver and carbon nanotubes. Conductive paths provide the possibility to use heating, that is always important for outer garments.

TECHNOLOGY: PRINTING ON ALUMINUM

suitcases • briefcases • bags • aluminum clothing

Direct printing on anodized aluminum with open pores. Colourants forming an image during the printing process penetrate the open pores of aluminum. After printing the pores are closed as a result of special heat treatment. Thus, a very durable image is obtained inside the anodized aluminum layer. The image is not subject to abrasion, it does not wear down over time, does not collapse under the influence of moisture and temperature changes throughout the entire service life of the aluminum product.