HIGH-PRECISION PRINTING TECHNOLOGY

IQDEMY designed the IQJET equipment line for goods production that require the highest accuracy in printing. The IQJET line can be adapted to production process of any enterprise. The IQJET line peculiarity is one piece stone body construction with magnetic high-precision motors.

Industrial speeds are achieved through the set of fast print heads. Print heads are installed on a solid rigid carriage, print heads operate at the highest frequencies due to electronics developed by IQDEMY.

Find out more information about the high-precision IQJET printer and the new IQJET NEO model by clicking HERE

- Indoor & Outdoor decoration

- Automotive & Aerospace

- Security & Brand Protection

- Advertising & Event-Marketing

- Consumer Electronics & Instrument-Making

- Technical Marking

- Medical & Pharmaceuticals

- Accessories & Clothes

AUTOMOTIVE & AEROSPACE

Printing is increasingly used in many applications, the talk will highlight the market developments with emphasis on the new opportunities across the automotive and transport system. Print is everywhere in cars, trucks, trains, ships and aerospace from dashboards, upholstery, windows, switches and dials– not including the durable labels also involved. It is a complex, fragmented supply chain where print expertise in highly necessary.

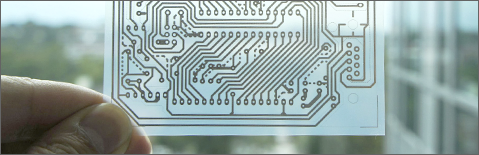

PRINTING OF ELECTRONICS BOARDS & DEVICES

In 2010 IQDEMY introduced inks that contain silver and are based on UV varnish. The importance of this project was motivated by the market demand for electronic circuits prototyping equipment. Inks composition undergone special tests, so this technology can be adapted to clients’ needs.

- Automotive & Aerospace

- Consumer Electronics & Instrument-Making

CONSUMER ELECTRONICS & INSTRUMENT-MAKING

Our equipment and special chemical compositions is able to print antennas, sensors, displays, and solar batteries etc. We integrate these elements with; paper, plastic film, fabric, ceramics, metals, and even large physical objects. We have the ability to custom: print, etch, laser cut, solder paste, and assemble on site. Our ability to add electronics directly onto the surface of preexisting physical objects, or inside/below the surface in some cases, can have significant benefits in terms of effectiveness and robustness.